Four-stroke engine: How it works and what are its advantages

A four-stroke engine, or colloquially four-stroke, is a piston combustion engine working in four strokes. This means that the working cycle of the engine will take place during four strokes of the piston and two revolutions of the crankshaft.

The work cycles are slightly different for spark and diesel engines depending on how the mixture is ignited. So let's look at how a gasoline four-stroke engine and a diesel four-stroke engine work.

Content

Four-stroke engine function

Since the working cycles of petrol and diesel engines are slightly different, we will talk about both separately.

Petrol four-stroke engine

1. Intake stroke

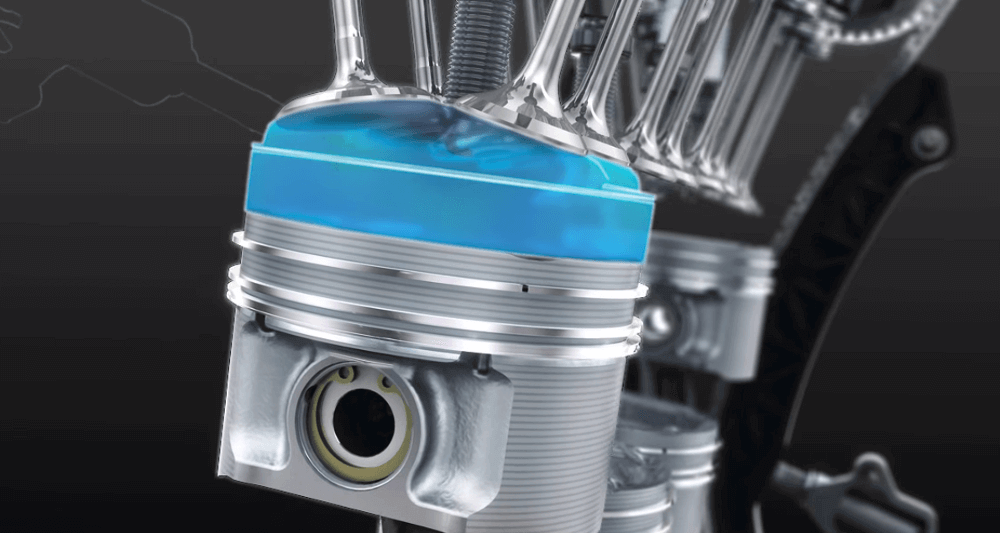

As the piston moves downwards, the space above the piston increases, and at the same time, the intake valves also open. This causes a drop in pressure above the piston (the pressure above the piston is lower than atmospheric pressure). This pressure difference will allow the engine to suck the necessary air into the cylinders through the intake pipe.

Engine Pistons: How do they work?

However, in addition to air itself, fuel also enters the cylinders. Air and fuel together form an ignitable mixture. The ignition mixture is formed in the intake channels, intake manifold, or cylinder, depending on the fuel injection technology.

2. Compression

After the piston reaches its bottom dead center and the intake phase ends, it begins to move upwards. The piston compresses the mixture with its upward movement, which heats up as a result, and because it cannot expand, the pressure also rises.

The high temperature and pressure promote the vaporization of the fuel and its mixing with air, making the mixture more explosive. However, the mixture must not be compressed too much during compression so that it does not reach the fuel's auto-ignition temperature (detonation combustion). During compression, the intake and exhaust valves are closed.

3. Expansion

During this phase, the combustion process begins. A spark jumps on the spark plug and ignites the compressed mixture. After ignition, the mixture begins to expand, pushing on the piston and moving it downwards to its bottom dead center, converting thermal energy into mechanical work.

4. Exhaust

During this phase, the exhaust valves open to allow the exhaust gas to exit the cylinder. At the end of the expansion, the pressure in the cylinder is higher than the atmospheric pressure, due to which the exhaust gases are forced out of the cylinder. The piston pushes out the remaining exhaust gases as it moves toward its top dead center.

However, to improve cylinder emptying, the exhaust valves close only after the piston reaches its top dead center and the intake valves are already open.

After all four cycles have finished, the engine's working cycle begins again.

Four-stroke diesel engine:

The principle of operation of a four-stroke diesel engine is very similar to the operation of a four-stroke petrol engine. The main difference is that only clean air is drawn into the cylinders. After being compressed and heated, diesel fuel is injected, and the resulting mixture is ignited by compression heat.

1. Intake stroke

The piston moves from its top dead center downwards to its bottom dead center, increasing the space above the piston and opening the intake valves. This makes the necessary amount of air enter the cylinders through the intake pipe.

2. Compression

After the piston reaches its bottom dead center and the intake phase ends, it begins to move upwards. The piston thus travels from its lower dead center back to its upper dead center while its upward movement compresses the air, which heats up as a result but also increases its pressure.

Just before the piston reaches its top dead center, fuel is injected into the combustion chamber, which is mixed, vaporized, and ignited, causing expansion.

3. Expansion

After the mixture is ignited, the thermal energy of the fuel is released by burning, which is manifested by an increase in gas pressure in the cylinder. Thus, the gas pressure acts on the engine piston, which converts the fuel's thermal energy into the engine's mechanical work. During expansion, the engine piston moves from its top dead center to its bottom dead center.

4. Exhaust

During the last part of the working cycle of a four-stroke diesel engine, the piston moves from its bottom dead center to its top dead center with the exhaust valves open. This means that the piston pushes the exhaust gases through the exhaust system into the air with upward movement. The exhaust valves are closed just before the piston reaches its top dead center.

Exhaust system: What are its main components?

The same applies to a diesel four-stroke engine and a petrol four-stroke engine. After all four cycles have finished, the engine's working cycle begins again.

A turbocharger is often used for four-stroke engines to create boost pressure. In the past, however, turbocharging of engines using a compressor was relatively widespread. But let's look at the advantages and disadvantages of a four-stroke engine compared to a two-stroke engine.

Advantages of a four-stroke engine:

Lower fuel consumption

More balanced and refined operation

Sufficient power even at lower speeds

Better lubrication system

Low engine oil consumption

Fewer emissions

Better engine cooling

Longer service life

Disadvantages of a four-stroke engine:

Higher weight

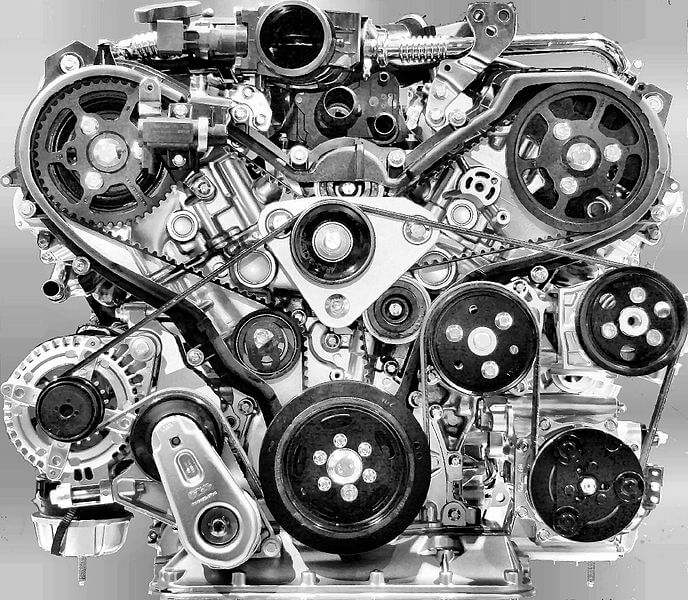

More complex design

More expensive repairs in case of failure

Two revolutions of the crankshaft and four strokes of the piston are required for one working cycle of the engine