Diesel Engine: How does it work, and what are its advantages?

A diesel engine is a piston combustion engine that often burns diesel fuel and converts thermal energy into mechanical work. Thermal energy is obtained in the engine by converting fuel into heat through combustion.

When fuel is burned, the temperature and pressure in the engine increase. The increased pressure of the working substance acts on the pistons of the engine, which convert this energy into mechanical work.

Content

How Does a Diesel Engine Work?

The diesel engine ignites the mixture of fuel and air through the high compressed air temperature in the combustion chamber. It is mostly constructed as a four-stroke but can also be constructed as a two-stroke.

Since most cars are equipped with four-stroke engines, we will describe the function of a diesel engine with four cycles. The principle of operation of a four-stroke diesel engine is very similar to that of a petrol engine.

The main difference is that with a diesel engine, only clean air is drawn into the cylinders, into which fuel is injected after being compressed and heated. Such a mixture is then ignited by compression heat, not by a spark from a spark plug, as with a petrol engine.

Four-stroke Diesel Engine:

1. Intake

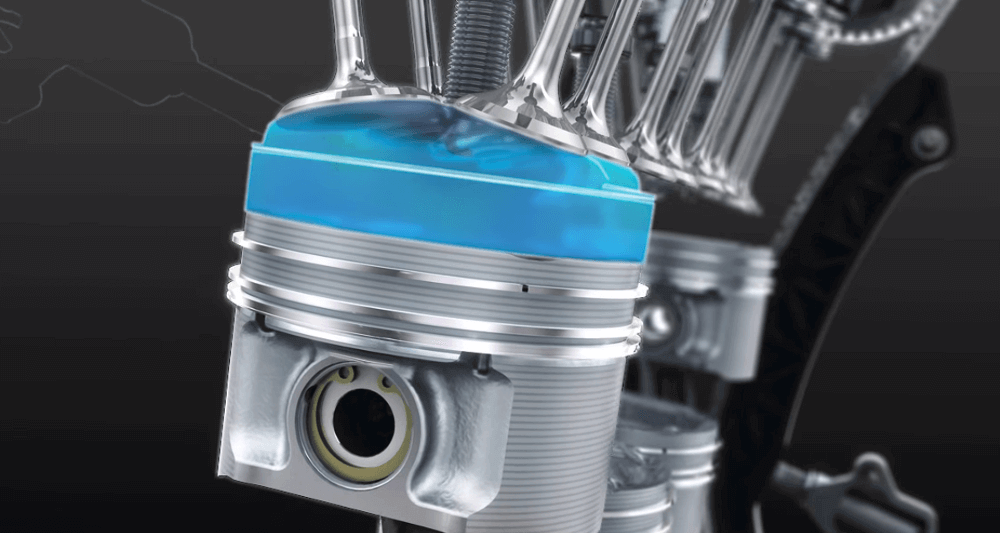

During intake, the engine piston moves from its top dead center down to its bottom dead center while the intake valves are open. The space above the piston thus increases, the intake valves are open, and air intake into the combustion chamber is thus enabled.

2. Compression

The compression phase occurs after the intake valves are closed. During this phase, the piston travels from its bottom center point upwards to its top center point, thereby compressing the air, which is heated due to this, and because it cannot expand, the pressure also rises.

Just before the piston reaches its top dead center, fuel (diesel) is injected into the compressed air, which atomizes, vaporizes, and ignites, creating expansion. The intake and exhaust valves are closed during this phase.

3. Expansion

During expansion, the piston moves from its top dead center down to its bottom dead center, with the intake and exhaust valves closed. The mixture is ignited, and heat energy is released, increasing the pressure in the cylinder. The pressure acts on the piston, pushing it down to the bottom dead center. In this way, thermal energy is converted into mechanical work.

4. Exhaust

During the final phase, the exhaust valves are open, and the piston moves from its bottom dead center position upward to its top dead center position, forcing the exhaust gases out of the cylinder. However, to improve cylinder emptying, the exhaust valves close only after the piston reaches its top dead center and the intake valves are already open.

These four cycles (phases) occur during two crankshaft revolutions and are constantly repeated.

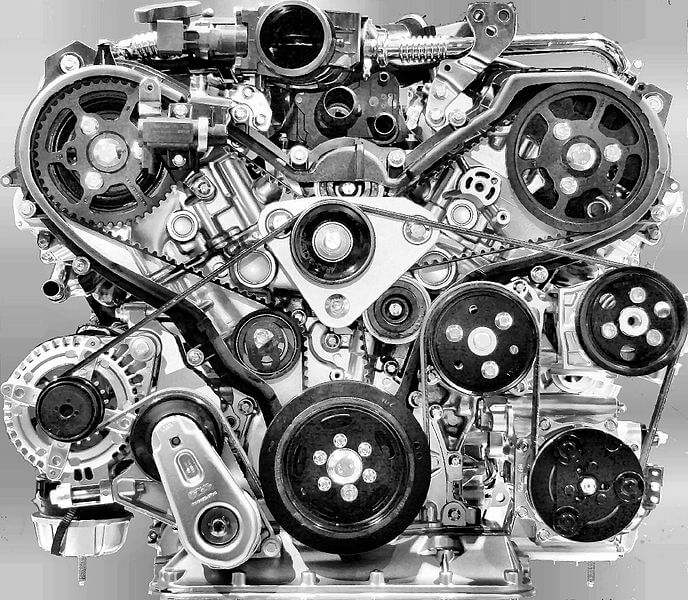

Diesel Engine Types

According to the design of the combustion chamber and the place of fuel injection, we distinguish diesel engines:

Direct injection engines - fuel injection and all combustion takes place in one main combustion chamber

Engines with indirect injection - fuel injection and the initial phase of combustion take place in a special space, in the chamber, and only then is it transferred to the main combustion space

Diesel Engine Power Regulation

The diesel engine's power is regulated by the amount of fuel injected into the combustion chamber with approximately the same air volume per work cycle.

So the richness, that is, the quality of the mixture changes. A variable amount of fuel the injection device supplies realizes power regulation.

Advantages and Disadvantages of Diesel Engine

Diesel engines are structurally more complex than petrol engines, but their performance is lower, mainly due to the combustion of a different fuel. When using the same technology and engine volume, the power of a petrol engine is always higher. However, the advantage of diesel engines is lower consumption and longer lifespan.

However, technology has advanced, and almost all diesel engines are now turbocharged or supercharged. Combined with a direct injection technology, their high performance, low fuel consumption, and fewer produced emissions are guaranteed.

These engines are suitable for long drives and not for short city wanderings, as the time required to warm up the engine to the operating temperature is much longer than in the case of a petrol engine.