MIVEC: Variable valve timing and valve lift

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System) is a designation for the engines of the automobile company Mitsubishi, equipped with a system of variable valve timing and valve lift.

This valve control system is used to improve the engine's volumetric efficiency, thereby increasing engine performance and reducing fuel consumption and the amount of emissions produced.

Content

What does MIVEC mean?

The abbreviation MIVEC is the trade name for variable valve timing and valve lift technology developed by the Mitsubishi automobile company. Not only spark but also diesel engines of the Mitsubishi brand are equipped with this technology.

Although the MIVEC system was designed to increase engine performance, it was subsequently redesigned to improve economy and emissions.

History of the MIVEC system in a nutshell

MIVEC was first introduced in 1992 in the 4G92 engine with a volume of 1597 cm3. It was a naturally aspirated engine, equipped with a DOHC distribution and 16 valves, used in the Mitsubishi Mirage and Mitsubishi Lancer models. This engine achieved a respectable output of 107 kW at 7,000 rpm for that time, largely due to the aforementioned system.

However, a much bigger revolution came in 2010, when Mitsubishi became the first to install diesel engines with variable valve timing and valve lift into mass-produced passenger cars.

It was a 1.8 DI-D MIVEC engine, which offered a power of 110 kW and a torque of 300 Nm. This engine was equipped with variable valve timing and lift, direct fuel injection using the common-rail system, and had an aluminum block, and plastic cylinder cover. It also featured a low compression ratio (14.9:1) for a diesel engine.

In the first years of the development of MIVEC technology, Mitsubishi also developed another variant of this system called MIVEC-MD. These technologies are almost identical, but the difference is that MIVEC-MD can close the intake and exhaust valves on two cylinders under a light engine load, reducing fuel consumption by 10 to 20%. This type of technology was discontinued in 1996.

How does MIVEC technology work?

As you probably already know, the variable valve timing system optimizes the engine parameters, which leads to an increase in engine performance, a reduction in fuel consumption, and the amount of emissions produced. However, some systems are only designed to change the valve timing, not the time the valves are open.

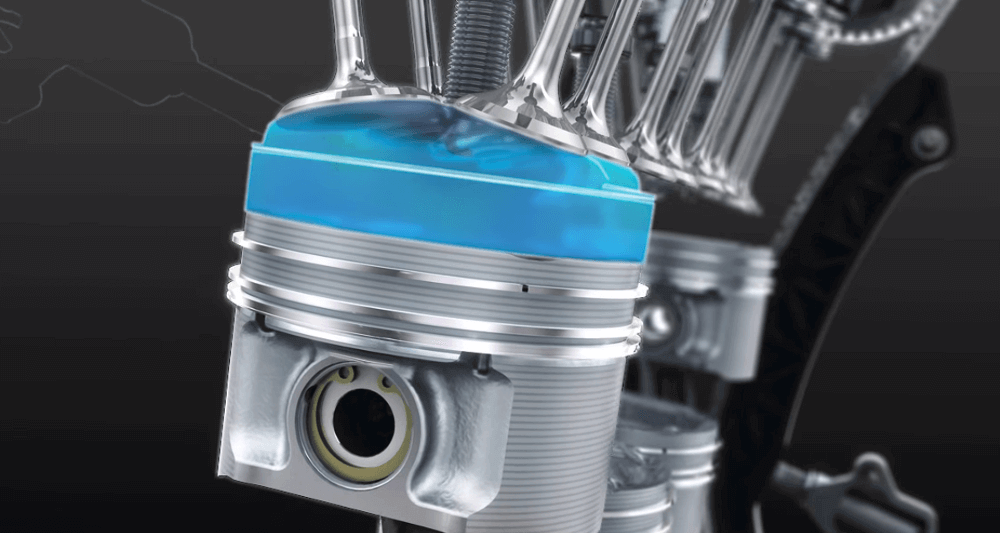

However, the MIVEC system controls the timing and valve lift, thereby changing the valve opening time and the length of the valve opening time. The basic function of this system is to change the cam profile, which adapts the engine performance to the driver's requirements.

Thus, MIVEC dynamically changes the cam profiles during different engine modes. A low-lift cam controls the low-load and high-speed modes, and a higher-lift cam controls the heavy-load and high-speed modes.

Therefore, this technology works on a similar principle as if you replaced classic cams with sharp cams. When replacing standard cams with sharp cams, you can achieve an increase in only one parameter, namely either the final engine power or torque increase, but not both of these parameters simultaneously.

Since MIVEC can change the cam profile dynamically, it is possible to achieve, in addition to both of these parameters, a reduction in fuel consumption and emissions at the same time.