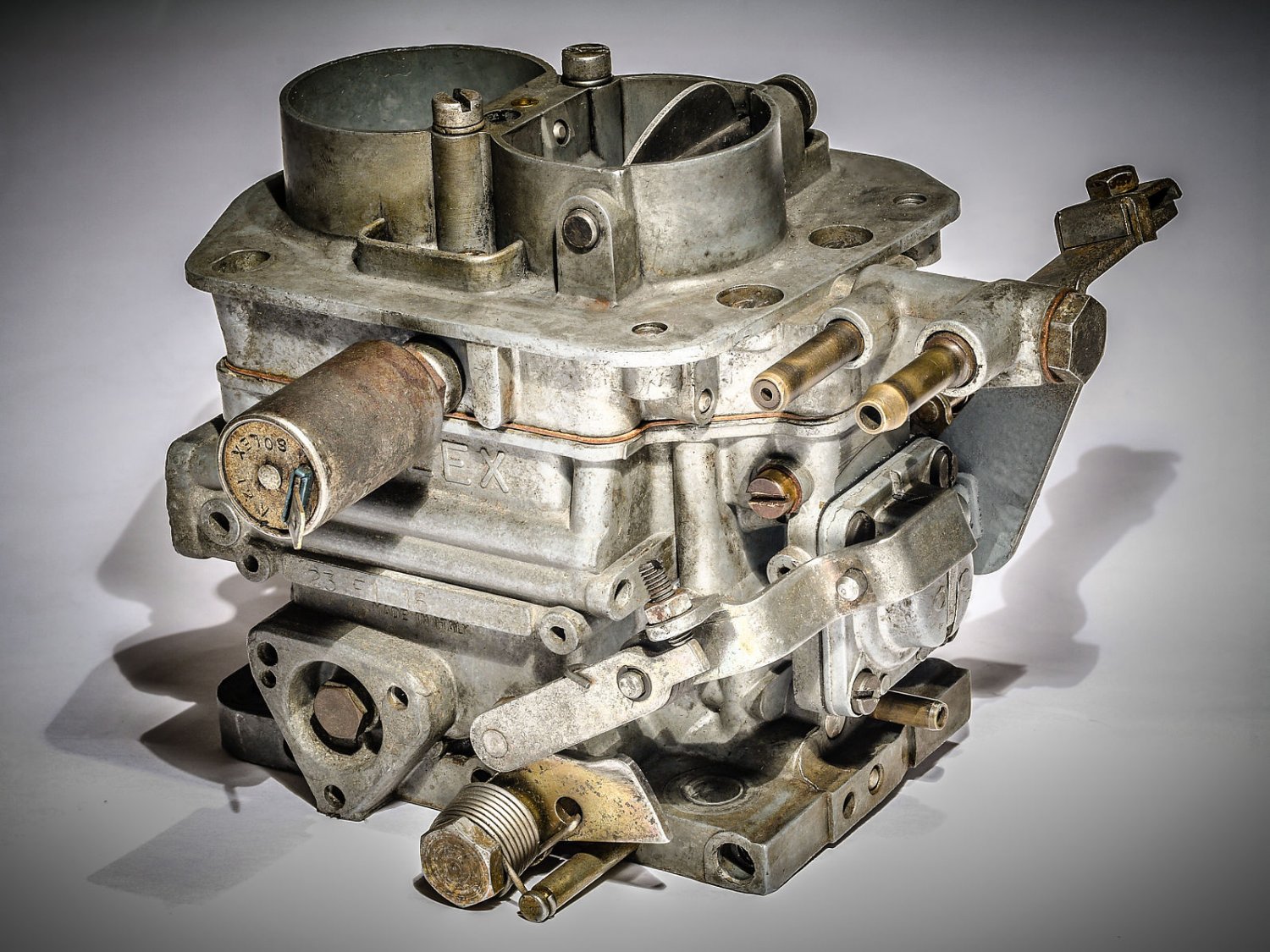

Carburetor: How does this device work?

A carburetor prepares the mixture for petrol engines that burn liquid fuel and air. This mixture's preparation consists of atomizing the fuel in the air stream.

Almost all spark-ignition engines used a carburetor in the past, but today it is replaced by injection devices.

Content

How does a carburetor work?

The fuel, which corresponds to the amount of air taken in, is sprayed by the injection nozzles under the fuel pump's pressure, and the air sucked into the engine flows through a nozzle with a variable cross-section. In this place, where the cross-section is narrowed, there is the outlet of the fuel nozzle from the float chamber while in this place, the speed of the airflow will increase, but its pressure will decrease.

As a result of the reduction in pressure, fuel is sucked out. After overcoming the narrowed cross-section, the airspeed decreases again. The fuel hitting the air begins to break up, resulting in a better atomization of the fuel in the air, resulting in a more homogeneous mixture, and this means that better combustion occurs.

The fuel supplied by the engine carburetor depends on the negative pressure in the diffuser - the higher the negative pressure, the greater the fuel dose. A diffuser is a channel with a gradually increasing or decreasing cross-section in the liquid or gas flow direction. The preparation of the mixture depends on the excess of air and, thus, on the ratio of the air contained in the mixture and the amount of air required for the perfect combustion of the fuel contained in the mixture.

The carburetor is thus dependent on excess air and vacuum in the diffuser. As the negative pressure increases, the percentage of fuel in the mixture increases. Thus, the excess of air in the mixture decreases.

Constant choke carburetor

Working principle

The constant choke carburetor maintains a constant air velocity through the venturi, irrespective of the engine load. As a result, it achieves a consistent air-fuel mixture for efficient combustion. The constant choke carburetor consists of a choke valve, main metering system, idle system, and accelerator pump.

Advantages

Optimal air-fuel mixture for efficient combustion.

Simple construction and fewer adjustments are required.

Reliable operation under various driving conditions.

Constant vacuum carburetor

Working principle

The constant vacuum carburetor maintains a constant pressure difference between the venturi and the float chamber. This type of carburetor has a variable venturi, which alters its size based on the throttle position. Key components include an air throttle, fuel metering needle, and air-bleed system.

Advantages

Precise control over the air-fuel mixture.

Improved fuel economy and reduced emissions.

Better performance across various engine speeds.

Multiple venturi carburetor

Working principle

The multiple venturi carburetor features two or more venturis arranged in series, each with its own metering system. This design enhances the atomization and mixing of fuel and air, offering improved performance across a wide range of operating conditions. It consists of primary and secondary venturis, metering rods, and power valves.

Advantages

Enhanced fuel atomization for improved combustion.

Better performance across varying engine loads.

Versatility for use in high-performance engines.

Operation of carburetor systems

In order to comply with emission limits but also for maximum performance and lowest possible consumption, car carburetors were often equipped with various auxiliary systems that enabled them to work economically and reliably in a wide range of engine speeds and loads.

Idle system

It is part of almost every car carburetor. It is located in the carburetor mainly because the main carburetor system consisting of the diffuser is not able to supply the engine with a suitable mixture at low engine speeds. After all, the air velocity is not sufficient for the perfect atomization of the fuel.

Supplying the engine with a homogeneous mixture at idling speed and partially also at low engine speeds and low engine load is ensured by the idling system, which is made up of a system of nozzles and air ducts that open into the idling channel and is led behind the mixture quantity regulator (damper).

Thus, if the gas pedal is not depressed, the valve almost completely closes the carburetor channel, which causes a large vacuum behind it. However, the high vacuum causes a large amount of fuel to be drawn from the idling system channel, which is regulated by means of nozzles to provide the engine with a suitable mixture during idling.

Transition system

The transition system is used during the transition from the idling speed mode to the full load mode and, together with the idling system, participates in supplying the engine with fuel. The transition system is located in the carburetor because when the gas pedal is gradually pressed, the underpressure drops behind the mixture amount regulator, which causes a decrease in the amount of fuel taken from the idling channel.

The bypass system is used when the accelerator pedal pressure approaches a level where the idle system can no longer drive the engine. The airflow through the carburetor is insufficient for the main system to take over the fuel supply.

That is why there are small holes in the carburetor chamber's wall located at the flap's level in flap-controlled carburetors. When the edge of the valve reaches the level of the hole in the carburetor wall, a vacuum occurs in the chamber, which creates a pressure difference in front of and behind the valve, and fuel begins to be taken from the transfer system.

When the valve is opened more, the idling system's share in the engine's fuel supply decreases and is gradually taken over by the transitional system.

Acceleration pump

The accelerator pump is an auxiliary system of the carburetor, which is used to eliminate adverse effects, such as, for example, a sudden change in power. If the engine is in the idling mode and the gas pedal is pressed hard, the carburetor flap will open rapidly, causing the idling system to be immediately deactivated.

With such a fast movement, the transition system does not have time to react, and since the engine has low revolutions, the main system cannot supply it with fuel. In such a situation, the engine would stop because it would not get enough fuel. For this reason, an accelerator pump is mounted on the carburetor, which immediately reacts to pressing the gas pedal.

With each press, the pump injects a certain amount of fuel into the carburetor channel, which depends on the speed of pressing the pedal, and thus compensates for the lack of fuel due to a sharp press of the pedal.

Enricher

An enricher is an auxiliary carburetor system that enriches the mixture in full power and heavy load modes. The enricher is often constructed as a secondary carburetor chamber, which does not contain an idling and transition system, but only the main system set to deliver full power.

In order to be able to deliver full power, it is necessary to start the concentrator in the mode where the maximum amount of air will flow through the secondary chamber.

Idle disconnector

This system was found in carburetors of a more modern design. This is a mechanical disconnection of the idling circuit intended to prevent self-ignition after engine shutdown. They occurred when the engine was scorching after driving, which caused the mixture to burn in the cylinder without needing a spark from the spark plug.

So the engine sometimes ran for a few seconds even after the ignition was turned off. Disconnecting the idling circuit prevents self-ignition because the engine has nothing to burn and thus stops.

Choke

After starting the engine, when the engine and the entire intake pipe are still cold, the ideal evaporation of the fuel does not occur. After being atomized in the carburetor, the fuel hits the cold walls of the intake manifold and condenses there, causing a lean mixture to enter the engine.

Such a mixture is unsuitable for engine operation and must therefore be temporarily enriched. The choke ensures this enrichment of the cold engine mixture.

Like any device, the carburetor can be damaged, and when repairing it, you should:

check the fuel supply to the carburetor

check or clean all carburetor nozzles

check channels and dirt traps (strainers)

remove condensed water in the fuel

check the float of the needle valve and accelerator pump

check the operation throttle valve